Product Description:

Desiccant Masterbatch is an additive for injection molding and film extrusion, aiding in lowering the moisture level in plastic materials. It contains 2-4% additive content, with a melting point ranging from 130-140°C. The volatile substance content is ≤0.5%, and the melt flow index (MFI) falls between 2-4. This desiccant masterbatch is engineered to deliver outstanding moisture-absorbing capabilities, minimizing the risk of water-related contamination in plastic items. It contributes to boosting the stability of plastics, ensuring they remain in good shape during storage and transit. Moreover, it can effectively lessen the absorption and movement of water into plastics, offering top-notch protection against dampness.

Features:

- Product Name: Desiccant Masterbatch

- Adding rate: 1-5%

- MFI (g/10min): 2-4

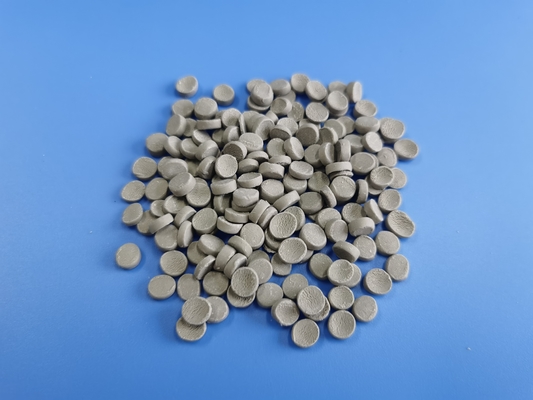

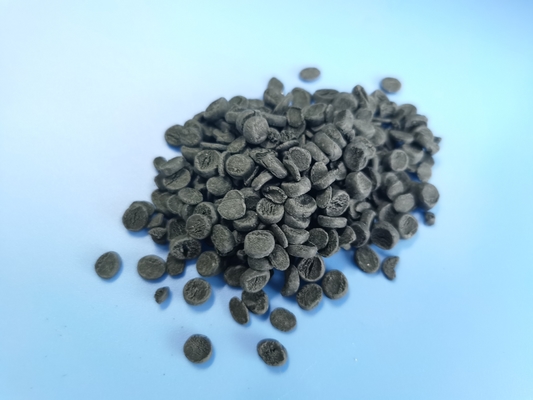

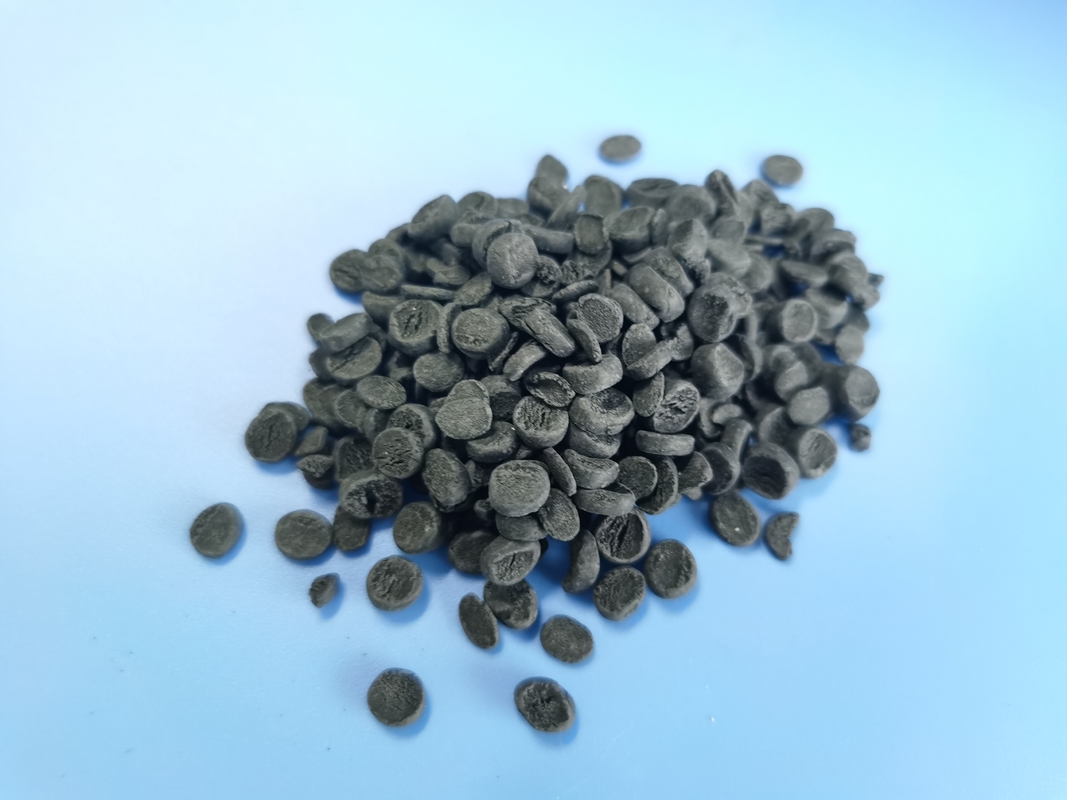

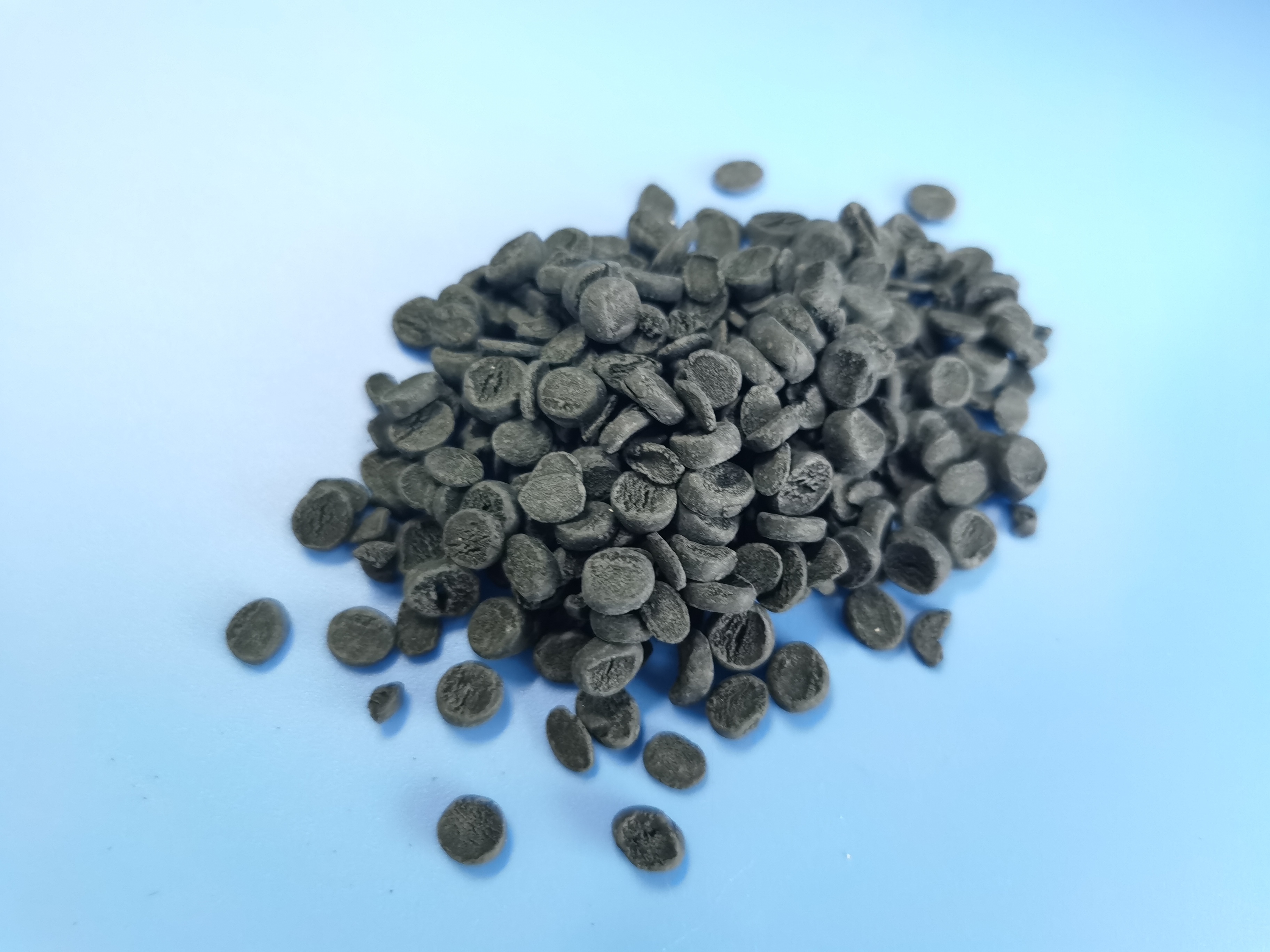

- Color: Grey

- Appearance: Granule

- Melting Point (°C): 130-140

- Plastic Additive: Yes

Applications:

Ecoplas PE-200S Desiccant Masterbatch: A Moisture-Absorbing Solution for Plastic Film

Ecoplas PE-200S desiccant masterbatch, a grey product produced in China, is utilized to soak up moisture in plastic film. It can be added to plastic film at a proportion of 1-5%, with volatile matter ≤0.5% and a Melt Flow Index (MFI) of 2-4. It serves as a dependable option for plastic film producers needing to manage moisture levels in their products.

Technical Parameters:

| Property |

Value |

| Product Name |

Desiccant Masterbatch |

| Category |

Plastic Material |

| Adding rate |

1-5% |

| Color |

Grey |

| Density (g/cm3) |

1.2-1.4 |

| Melt Flow Index (MFI) |

2-4 |

| Melting Point (°C) |

130-140 |

| Ash Content (%) |

≤0.2 |

| Packing |

25kg/carton |

Customization:

Customized Desiccant Masterbatch

Ecoplas PE-200S

Our desiccant masterbatch is a type of plastic additive, specifically developed for films. It has a grey granule look, with volatile matter ≤0.5% and additive content of 2-4%.

Manufactured in China, this desiccant masterbatch is a perfect pick for film uses, as it can shield the film from moisture.

If you’re seeking a trustworthy and economical plastic additive, Ecoplas PE-200S Desiccant Masterbatch is the right choice.

Place your order now to get the finest desiccant masterbatch for your film applications!

Support and Services:

Technical Support and Service for Desiccant Masterbatch

We provide technical support and service to make sure your Desiccant Masterbatch functions properly and effectively.

Our skilled technical staff is ready to assist with setup, upkeep, problem-solving, and other needs.

We also provide a range of training courses to help you maximize the benefits of your Desiccant Masterbatch. Our specialists will give thorough guidance on the product's features, functions, and the best ways to use it effectively.

Our team is dedicated to helping you get the most out of your Desiccant Masterbatch. Reach out to us today with any questions or requests you may have!

Packing and Shipping:

Desiccant Masterbatch is packed and transported in moisture-resistant containers with temperature-regulating functions. These containers are designed to keep the product sealed and dry until it arrives at its destination. They are also fitted with an airtight seal to stop moisture from getting into the product.

The packaging and shipping of Desiccant Masterbatch are closely supervised during transportation. The temperature and humidity inside the containers are tracked, and any fluctuations are recorded. Additionally, the containers are equipped with a tracking system to guarantee that the product is delivered on schedule and in good condition.

Desiccant Masterbatch is shipped in line with international standards and regulations. The product undergoes inspection and testing before being packaged and shipped. It is also checked for any signs of contamination or damage prior to shipment.

FAQ:

Q: What is Ecoplas Desiccant Masterbatch?

A: Ecoplas Desiccant Masterbatch is a PE-200S masterbatch developed by Ecoplas in China. It is a desiccant masterbatch used to take in moisture from the air.

Q: What are the advantages of Ecoplas Desiccant Masterbatch?

A: Ecoplas Desiccant Masterbatch is highly effective at absorbing moisture from the air, which helps lower the humidity in the surroundings. It is also non-toxic and has no smell.

Q: How does Ecoplas Desiccant Masterbatch work?

A: Ecoplas Desiccant Masterbatch operates by soaking up moisture from the air. It can take in up to 20 times its own weight in moisture.

Q: What are the applications of Ecoplas Desiccant Masterbatch?

A: Ecoplas Desiccant Masterbatch is frequently used in packaging and storage to avoid moisture damage. It can also be applied in the manufacturing of plastics and rubber products.

Q: Is Ecoplas Desiccant Masterbatch safe to use?

A: Yes, Ecoplas Desiccant Masterbatch is safe for use and contains no harmful chemicals. It is also non-toxic and odor-free.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!