Moisture-Control Anti-Foaming Masterbatch (LDPE Carrier) for Recycled Polymer Processing

Efficient Desiccant Flame Retardant Masterbatch (LDPE-Based) – Tailored Compositions Offered

Anti-Humidity Anti-Foaming Pellets for Reprocessed Plastic Manufacturing

Product ID: PE-200

Technical Details

Primary Use:

Reduces moisture-induced imperfections in recycled polyethylene and polypropylene during blown film and injection molding operations.

Suggested Loading:

Begin trials at 2% loading (may be modified according to material moisture condition).

Ideal For:

✔ Processors working with recycled PE/PP materials

✔ Producers utilizing virgin resins subjected to humidity

✔ Common uses: Film blowing, extrusion sheeting, injection molding

Main Advantages:

• Removes the need for pre-drying — lowers energy consumption

• Increases manufacturing throughput

• Works with a variety of polymer systems (including flame-retardant compounds)

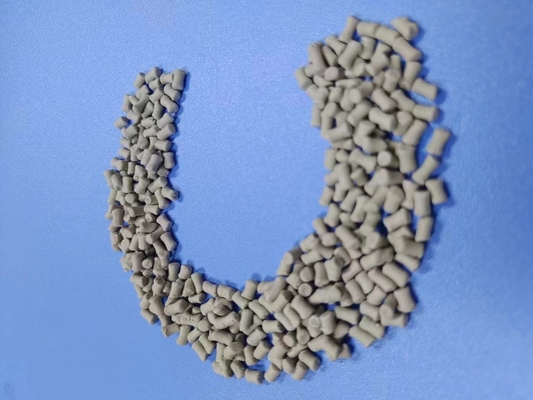

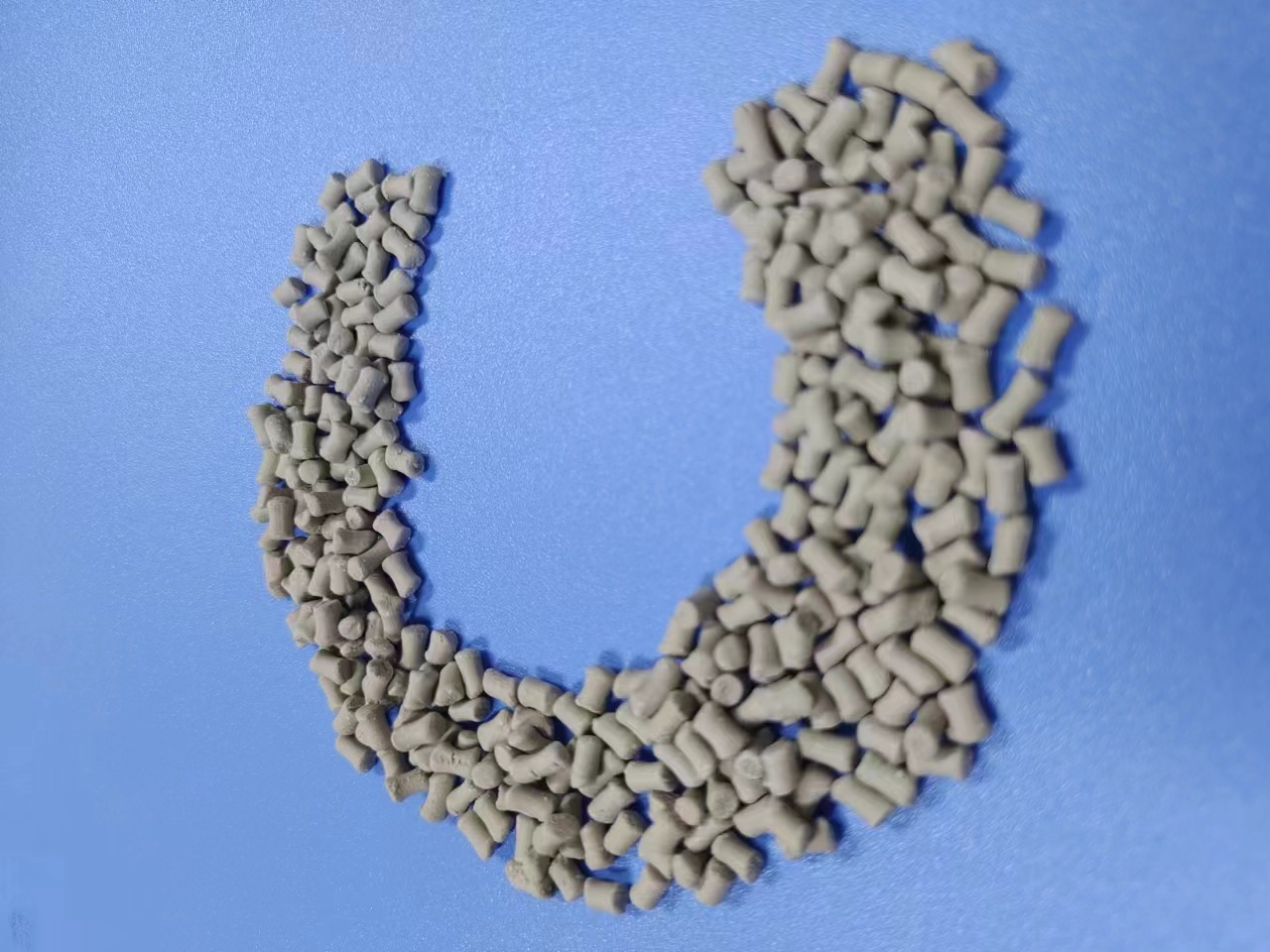

• Pellet form enables straightforward mixing with base materials

Instructions for Use:

1. Blend thoroughly with raw polymer prior to processing

2. Can be introduced via dedicated feeder systems

Note: Particularly effective in pipe and sheet extrusion lines

Packaging & Shipping:

• 25 kg sealed moisture-resistant bags (26 tons per 20ft container)

• Transport by sea advised

| Technical Parameters |

| Property |

Value |

Unit |

Test Standard |

| Carrier Resin |

PE |

/ |

/ |

| Additive Type |

Inorganic Moisture-Absorbing Functional Powder |

/ |

/ |

| Density |

1.7( +/- 0.05) |

g/cm3 |

GB/T1033-86 B |

| Melt Flow Index |

<3.00 |

g/10min (200℃/2.16Kg) |

GB/T3682-2000 D |

| Moisture Content |

<0.1 |

% |

IR |

| Powder Fineness |

800 |

Mesh |

/ |

| Particle Size |

4 ( +/- 0.5) |

mm |

/ |

| Processing Range |

140-320 |

℃ |

/ |

Company Overview (Founded 2007, Guangdong):

Quality Control:

• Prototype testing before full manufacture

• Comprehensive batch inspection prior to dispatch

Product Portfolio:

→ Desiccant additives

→ Standard and custom color masterbatches

→ Filler and clarity enhancement compounds

Key Strengths:

• Over 14 years of focused masterbatch production

• Customized manufacturing solutions (OEM/ODM)

• Dedicated engineering support

Service Provisions:

• Shipping terms: FOB, CFR, CIF

• Payment options: T/T, L/C

• Customized packaging arrangements

Frequently Asked Questions

————————————————————————————————————————————————————————————————————————————

Samples: Complimentary test samples provided upon request approval

Timelines:

• Quotation provided within 12 hours

• Production timing varies with order volume

Shipping Access: Located near Shenzhen port for efficient export operations

Certifications: Full suite of quality and compliance documents available upon request

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!