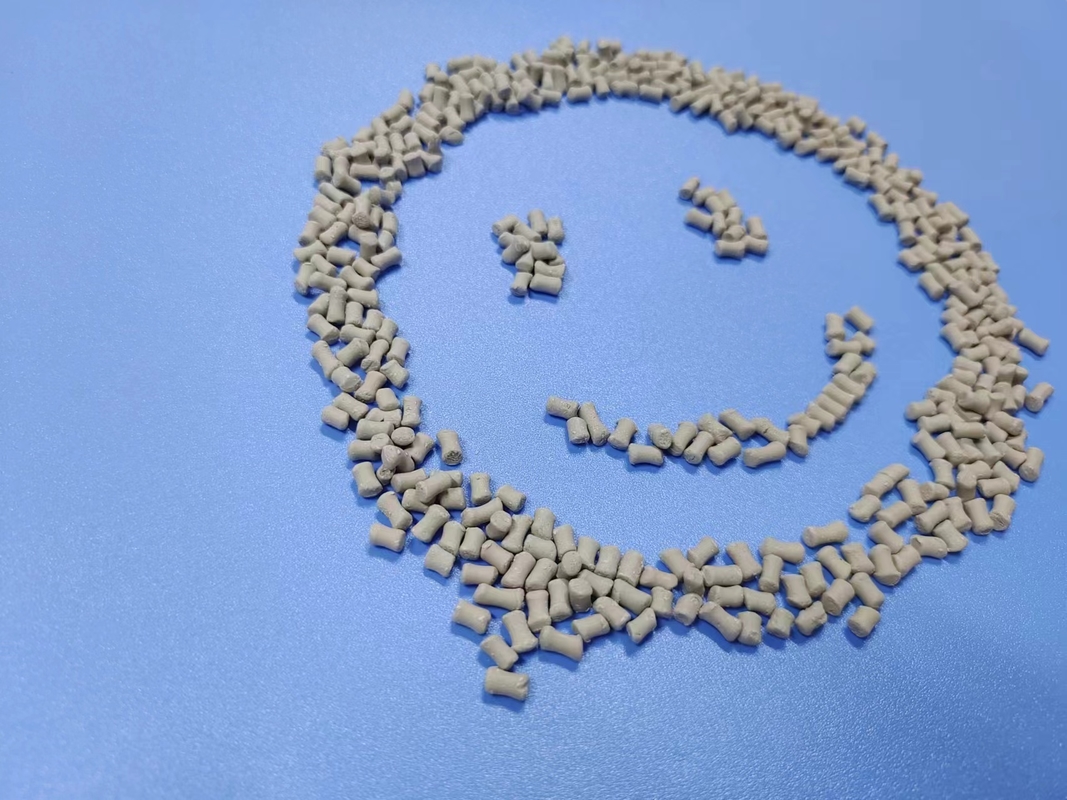

Moisture Absorbing Desiccant Masterbatch for Recycled Resin in Injection Moulding and Pipe Production

Desiccant Masterbatch with Moisture Absorption for Recycled Resin in Bags, Injection Moulding, and Pipes

This Desiccant Masterbatch is specially formulated to eliminate moisture and prevent foaming in recycled polymers including PE, PP, PS, ABS, and EVA during processing. A key advantage is its ability to actively absorb water throughout production, allowing recycled scraps and granules to be used directly without pre-drying—while still achieving high-quality end products.

Key Benefits of Desiccant Masterbatch:

- Cost Reduction: Lowers overall production expenses.

- Energy Efficiency: Removes the need for energy-consuming drying steps.

- Enhanced Product Quality**: Improves mechanical strength and visual appearance of plastic items.

- Safe Handling: Non-toxic, free of odor, non-corrosive, and safe for users.

- Superior Moisture Absorption: Rapid and effective water uptake.

- Corrosion Resistance: Helps protect processing machinery.

- Uniform Dispersion: Blends evenly within the polymer matrix.

Applications:

Who Should Use It?

- Factories utilizing recycled PE or PP resins.

- Processors working with virgin PP or PE that has been exposed to moisture.

- Suitable for products such as injection or blown films, sheets, and pipes.

Why Choose It?

- Powerful dehydration eliminates pre-drying.

- Reduces production time and costs.

- Compatible with a wide variety of polymer types.

- Convenient granule form for easy handling and blending.

How to Use?

- Blend the masterbatch with base resin prior to injection or blowing.

- Alternatively, use an automatic feeder directly from the masterbatch container or pre-mixed material hopper.

- Proceed with standard processing techniques. The injection grade is ideal for pipes and sheet products.

Specification:

|

Product Name

|

Desiccant masterbatch / Absorbent Masterbatch

|

|

Color

|

Grey White

|

|

Appearance

|

Granules

|

|

Function

|

Removes moisture in recycled and other materials to enhance product quality

|

|

Carrier

|

PE

|

|

Active Ingredient

|

CaO

|

|

Sample Availability

|

Free

|

|

Adding Ratio

|

1-5%

|

|

Applications

|

Blown film, injection molding, pipes, sheeting

|

Packaging & Delivery:

- 25 kg/bag, 26 tons per 20ft container

- 25 kg/carton, 23 tons per 20ft container

- Sea shipping recommended (20ft container)

FAQ

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Who are we?

Based in Guangdong, China, we have been manufacturing and supplying Desiccant Masterbatch, Black, White, Color, and Filler Masterbatches since 2007 to a global clientele.

2. How do we ensure quality?

We conduct pre-production sampling and thorough final inspections prior to all shipments.

3. What products do we offer?

Our range includes Desiccant Masterbatch, Black, White, Color, Filler, and Transparent Masterbatches, available as standard or customized.

4. Why choose us over other suppliers?

With over 14 years of expertise, we are a leading manufacturer of desiccant and color masterbatches in China. Since 2007, we have provided innovative solutions tailored to the evolving needs of the plastics industry. Many of our clients have maintained long-term partnerships with us from the beginning.

5. What services do we provide?

We accept delivery terms such as FOB, CFR, and CIF, and payment methods including T/T and L/C. We also support product customization and private labeling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!