Product Description:

Defoaming Masterbatch is a specialized antifoam additive formulated with polypropylene resin, desiccants, and other components. It is suitable for a wide range of thermoplastic processes including injection molding, extrusion, and blow molding. This masterbatch delivers excellent defoaming and drying performance, effectively minimizing foam formation during production, thereby enhancing product surface quality and manufacturing efficiency. Additionally, it helps lower defect rates, saving both material and operational costs. It is an optimal solution for manufacturers aiming to reduce foam and improve end-product quality.

Features:

- Product Name: Defoaming Masterbatch

- Effective Duration: 24 hours after opening

- Dispersion Quality: Excellent

- Melting Point: 110-130℃

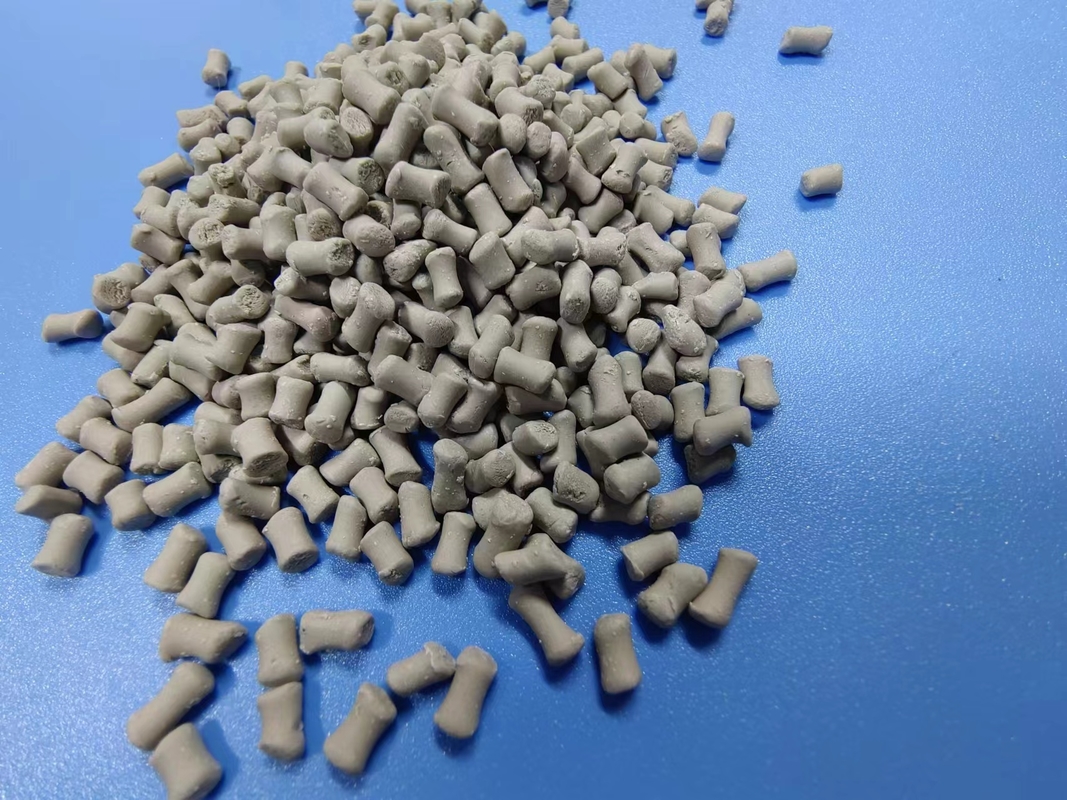

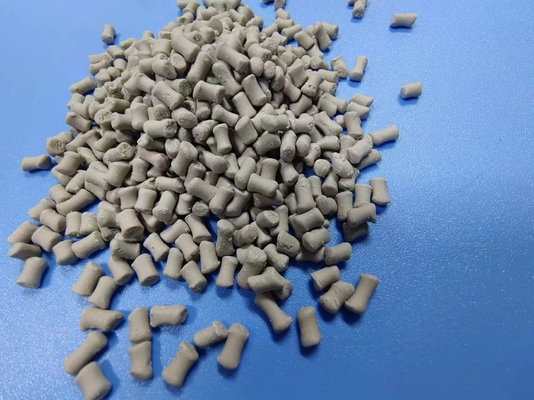

- Appearance: Grey Granules

Applications:

Ecoplas Material’s Defoaming Masterbatch, model PE-200S, is an anti-moisture and desiccant masterbatch manufactured in China. With a melting point of 110–130°C, density of 1.2–1.4 g/cm³, pH value between 6 and 8, and heat resistance of ≥80°C, this product contains ≤0.3% moisture, making it highly effective in preventing humidity-related issues. It is widely used in automotive components, window profiles, and other moisture-sensitive applications. The masterbatch functions by absorbing ambient moisture, preventing deformation, cracking, and corrosion, while also improving material strength and durability.

This defoaming masterbatch offers an efficient solution for controlling moisture in various industrial settings, including automotive, construction, and electronics. It can be applied as a protective coating on parts such as engine blocks to resist corrosion, or incorporated into window frames to avoid moisture-induced warping. It is easily blended into plastics, rubber, and resins, providing reliable moisture protection for industries requiring strict humidity management.

Customization:

Customized Defoaming Masterbatch Service

We offer tailored defoaming masterbatch solutions under the brand Ecoplas Material, model PE-200S, originating from China. Key properties include heat resistance ≥80°C, ash content ≤0.3%, gray granular appearance, and density of 1.2–1.4 g/cm³. This product serves as an efficient anti-moisture and desiccant agent with superior defoaming capabilities.

Support and Services:

Technical Support and Service for Defoaming Masterbatch

We deliver comprehensive technical support and services for our defoaming masterbatch products. Our skilled team offers the following assistance:

- Guidance on product application

- Troubleshooting for performance-related issues

- Help with product selection

- Recommendations for product optimization

We are dedicated to providing exceptional customer service and technical expertise. Should you have any inquiries, please do not hesitate to contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!