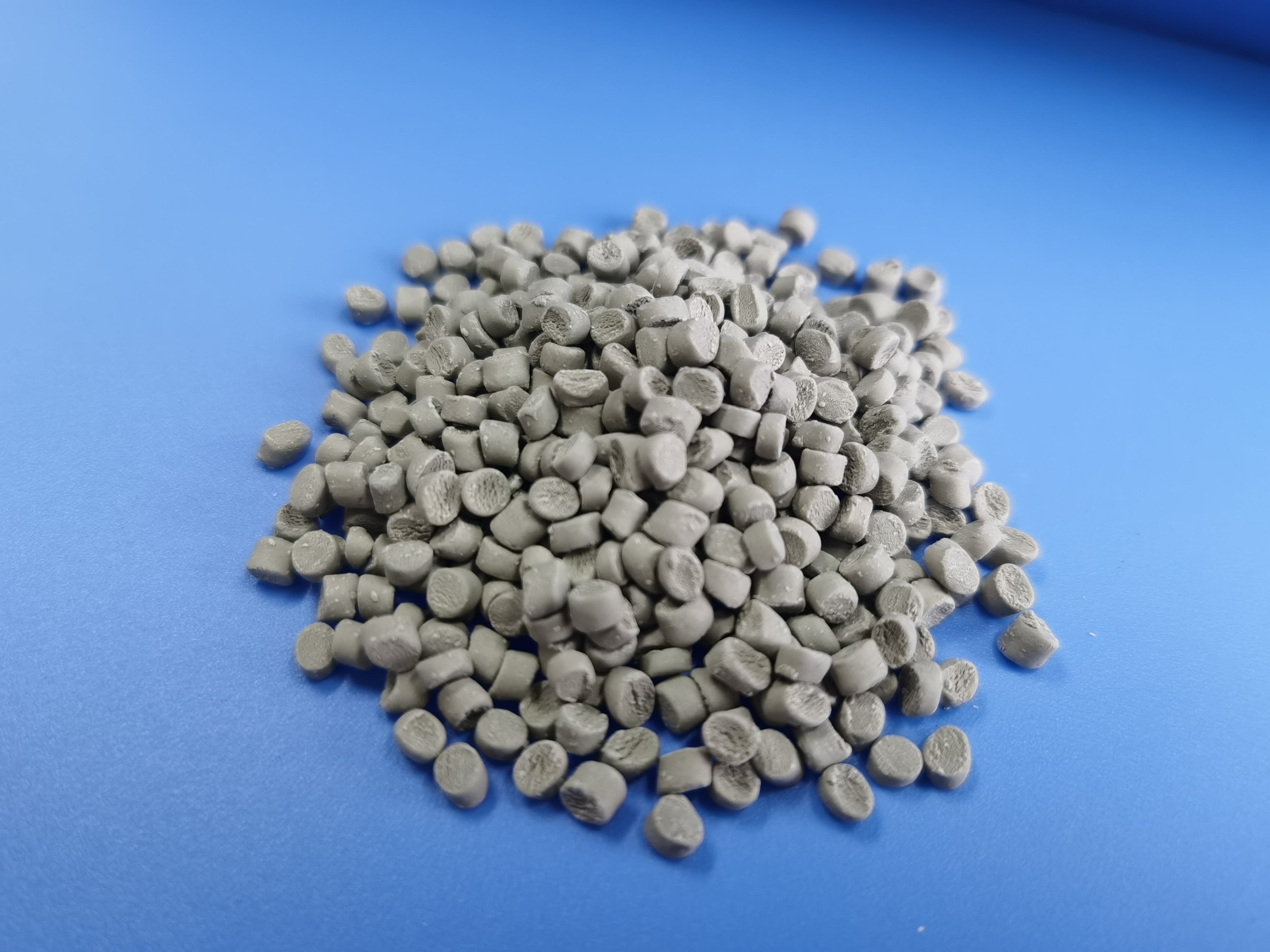

Plastic Defoaming Masterbatch Solves Moisture-Related Issues in Recycled PE Materials

The PE108 Defoaming Masterbatch boasts strong price appeal. Lab tests confirm a 24-hour shelf life once the bag is opened.

Primary Benefits

Skip Drying, Go Straight to Production

Conventional drying methods are both time-consuming and energy-draining. With this plastic dehydrating concentrate, just mix it with damp raw materials at a 1%-5% ratio to banish moisture-caused problems like blisters, haze, and fractures. Removing the drying stage slashes energy use by over 30%.

Wide-Ranging Compatibility

It works with a variety of plastics—PE, PP, PVC, ABS included—and accommodates processes such as blow molding, injection molding, fiber extrusion, and sheet fabrication. It’s particularly effective for recycled materials and those impacted by moisture.

Eco-Conscious and Energy-Saving

By eliminating drying, it cuts carbon emissions, supporting businesses in their green transition. The concentrate is non-toxic, scent-free, and SGS-approved, meeting all safety and environmental regulations.

Elevates Quality, Cuts Expenses

It reduces defect rates from moisture, enhances the surface finish and mechanical strength of final products, and trims costs related to labor, equipment upkeep, and energy. Total savings add up to 15%-20%.

Practical Uses:

Blow Molding: Add about 2% to resolve blister issues in films and plastic bags.

Injection Molding: Add around 2% to eliminate water marks and blemishes on molded parts.

Recycled Material Handling: Mix directly with damp recycled pellets—no extra steps needed—to keep production running smoothly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!